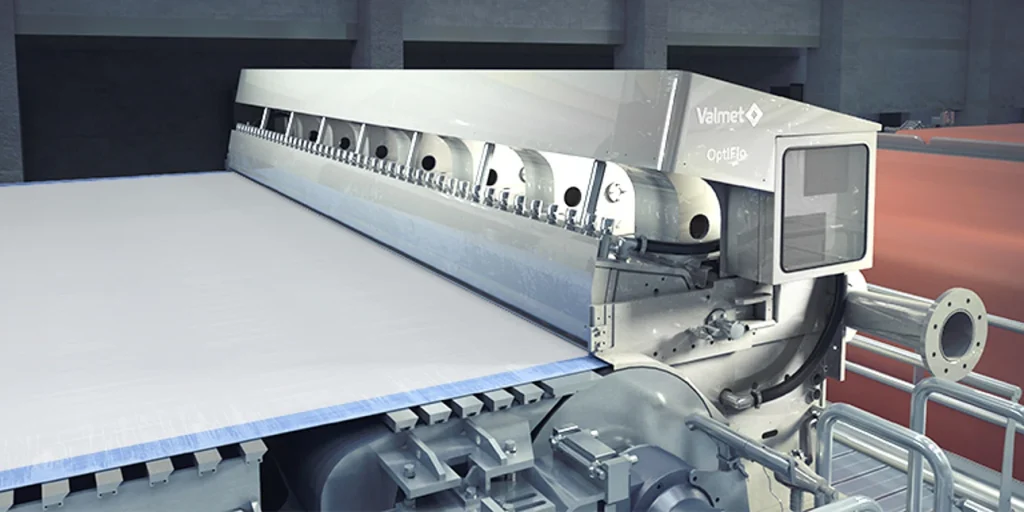

Headbox in the paper production line is a part of the paper making machine that has the task of evenly distributing paper pulp on the surface of the wire. The headbox is placed at the beginning of the paper forming stage and applies the pulp to the web surface with precision and control.

The main task of the headbox is the uniform and proportional distribution of paper pulp on the grid surface. For this purpose, the headbox includes a distribution plate, which uses thin weaves or small holes to pass the paste flow through it uniformly and distribute it homogeneously along the grid surface.

Paper pulp enters through stock pipes and collects in the headbox. Then, using the distribution plate, the dough is distributed and placed in a uniform layer on the grid surface. This layer of pulp is formed as the most basic layer of paper and the process of structuring and drying it begins.

Headbox is one of the important factors that affect the final quality of produced paper. The distribution plate of the headbox must accurately have the ability to distribute the pulp evenly so that the differences in paper thickness are minimized and a uniform and quality paper surface is produced.

Pressure Headbox: (Pressure Headbox) is a type of headbox that is used in papermaking production lines. In this type, the pulp is distributed to the grid surface using hydraulic pressure.

The main task of the pressurized headbox is to distribute the pulp evenly and control its thickness along the grid surface. The pulp inside the headbox is pressurized using a pump and injected to the grid surface through the distribution plate. The pressure created in the headbox helps to precisely control the dough distribution and reduce thickness fluctuations.

Headbox under pressure is usually used in papermaking lines with high speed and high accuracy in pulp distribution. Adjustable hydraulic pressure in the headbox helps produce paper with uniform and controlled thickness. Also, by using the pressurized headbox, it is possible to distribute the pulp at a high speed and improve the final quality of the paper by reducing thickness losses and thickness fluctuations.

In general, pressure headbox is one of the important tools in papermaking production lines, which helps to accurately control and improve pulp distribution and final paper quality.

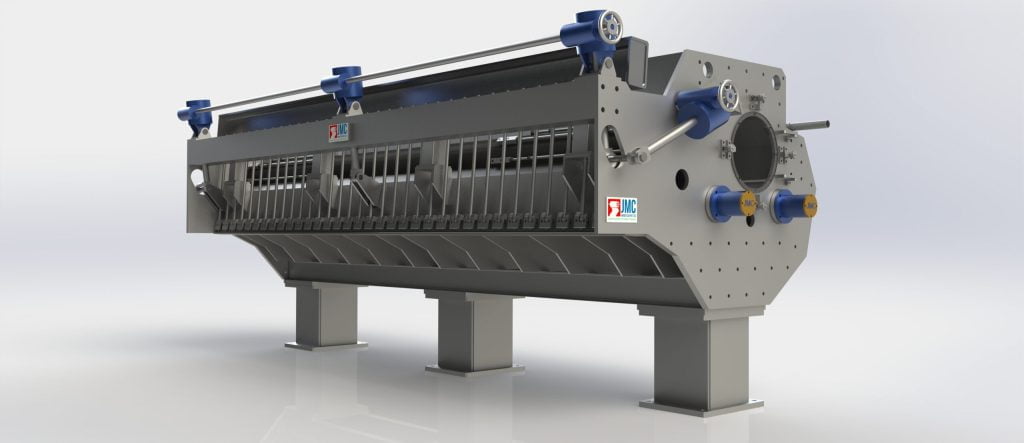

Synchronized Headbox: (Synchronized Headbox) is a type of headbox that is used in paper production lines. This type consists of two or more independent headboxes that operate simultaneously.

The main purpose of using a synchronizer is to distribute the pulp at different ratios across the width of the paper. This type has the ability to distribute simultaneously and independently of different layers of dough. In other words, it is possible to distribute paper pulp accurately and simultaneously in different layers of paper by using synchronized headbox.

By using synchronization, it is possible to increase the variety of thickness and properties of produced paper. For example, in a synchronized headbox, paste with a different ratio in terms of thickness can be injected into the inner and outer layers of paper, so that the result is paper with different characteristics in different layers.

Using a synchronized headbox helps to produce paper with more precise control over its thickness and properties. Also, this type of headbox has the ability to correct thickness fluctuations and helps to improve the uniformity and final quality of the paper.

Flow Distributor Headbox: Flow Distributor Headbox is a type of headbox that is used in paper production lines. This type is used for uniform distribution of paper pulp on the grid surface.

The main function of the floatation is to distribute paper pulp horizontally and vertically on the grid surface. This headbox has a distribution plate with associated braids. The pulp enters the headbox through several distribution pipes and then is transferred to the grid surface through this distribution plate.

By using floatational, paper pulp distribution is done with high precision. This headbox helps to accurately control the distribution of the paste across the width of the paper and prevents thickness losses and fluctuations in the final thickness of the paper.

Flotational headbox improves the uniformity of the produced paper and improves the final quality of the paper. By using this headbox, it is possible to improve the variety of thickness on the surface of the paper and help to produce paper with various properties and according to the needs of customers.

In general, the flotation headbox is one of the important tools in paper production lines that helps to accurately control and improve pulp distribution and final paper quality.

49 Responses

It was a useful article in a concise and practical way

We are glad that this article was useful to you

katana

Your writing is like a well-tuned instrument, each word and sentence perfectly balanced to create something beautiful.

Good shout.

Nice

Nice

NG

live resin gummies area 52

live rosin gummies area 52

snow caps weed area 52

live resin area 52

thc gummies for anxiety area 52

thc gummies for sleep area 52

buy pre rolls online area 52

sativa vape area 52

live resin carts area 52

microdosing edibles area 52

thc oil area 52

distillate carts area 52

thcv gummies area 52

thca diamonds area 52

disposable weed pen area 52

best indica thc weed pens area 52

full spectrum cbd gummies area 52

hybrid disposable area 52

thc tincture area 52

thca vape area 52

infused pre rolls area 52

weed vape area 52

thca gummies area 52

indica gummies area 52

thc gummies

best thca area 52

liquid diamonds area 52

thca disposable area 52

hybrid gummies area 52

liquid thc area 52

https://t.me/s/Magic_1win

https://t.me/s/Official_1xbet_1xbet

https://t.me/s/Official_ROX_ROX

https://t.me/s/reyting_online_kazino/5/Top_5_kazino_s_litsenziei

Получи лучшие казинo России 2025 года! ТОП-5 проверенных платформ с лицензией для игры на реальные деньги. Надежные выплаты за 24 часа, бонусы до 100000 рублей, минимальные ставки от 10 рублей! Играйте в топовые слоты, автоматы и live-казинo с максимальны

https://t.me/s/RuCasino_top

Получи лучшие казинo России 2025 года! ТОП-5 проверенных платформ с лицензией для игры на реальные деньги. Надежные выплаты за 24 часа, бонусы до 100000 рублей, минимальные ставки от 10 рублей! Играйте в топовые слоты, автоматы и live-казинo с максимальны

https://t.me/s/TopCasino_Official

Лучшие казинo в рейтинге 2025. Играйте в самое лучшее интернет-казинo. Список топ-5 казино с хорошей репутацией, быстрым выводом, выплатами на карту в рублях, минимальные ставки. Выбирайте надежные игровые автоматы и честные мобильные казинo с лицензией.

https://t.me/s/luchshiye_onlayn_kazino

https://t.me/s/Reyting_Casino_Russia

https://t.me/Martin_officials

https://t.me/s/officials_1xbet_1xbet

188v vom cung cấp cho người chơi hơn 35+ ngân hàng nội địa đi kèm với nhiều phương thức giao dịch khác bao gồm: Ví điện tử, Thẻ cào, QR Pay và USDT. Bạn chỉ mất 18 giây để nạp tiền và 2 phút để rút tiền thành công về tài khoản chính chủ, tất cả đều miễn phí và xanh chín. TONY12-15