Paper recycling means reusing waste paper and producing new products. Usually, recyclable papers are the same type that you use daily at home and at your workplace and you no longer need them. Therefore, all those magazines that have become old, or offices that are from years ago, or even company documents that are entered into the system and their paper version is not necessary, are suitable wastes for recycling.

Collect and transport

The first step in the paper and cardboard production process is collecting and transporting recyclable paper to the factory. This critical step involves collecting recyclable paper, which can be from homes, stores, offices, or recycling centers. These collected papers are transported to paper and cardboard factories.

After collecting and entering the factory, the stage of separation and separation is done. At this stage, the papers are separated based on their type and characteristics and are transferred to the next stages. This process is of particular importance because the final quality of the produced paper depends on the correct separation and separation. These measures also help improve SEO and reduce paper waste.

Separation and separation

Separation and separation of paper is one of the vital steps in its recycling process. Once the papers are collected and brought into the mill, there are many different types of paper and their uses, including writing paper, glossy, kraft, balky, notebook, and others.

In general, whiter and lighter quality papers are considered to be of higher quality than color printing papers. At this stage, papers are sorted based on quality, gender, and other characteristics. In addition, any other types of waste such as plastic or metals are also sorted and separated. These works help to improve the final quality of produced paper and play an effective role in reducing waste.

Also, the process of separation and separation of papers from other waste increases efficiency and productivity in the production process. These measures accelerate the proper sorting and recycling of papers and ultimately save natural resources and reduce environmental pollution. In addition, this type of operation is not only economically effective, but also environmentally effective.

Due to the high importance of separation and correct separation of papers, this process requires the use of modern and capable technologies. This also shows the importance of proper management of resources and increasing efficiency in the field of paper recycling.

In general, the sustainability and quality of paper recycling activities can have an effect on increasing productivity and improving the environment. The correct implementation of these steps is not only economically effective, but also helps to preserve natural resources and reduce pollution.

Finally, improving the separation and separation process of papers plays a very important role not only in reducing the waste of natural resources and the environment, but also in increasing the quality and strength of the final products.

shred (shredding paper)

After the stage of separation and separation of papers, the next stage consists of shredding the papers into smaller sizes. This step, known as shredding, has several key advantages that can be effective in increasing productivity and reducing material wastage.

One of the most important advantages of shredding is increasing the speed of the paper pulping process. The smaller dimensions of the papers make the pulping process easier and faster, which helps improve efficiency and productivity.

In addition, shredding papers leads to a reduction in their depreciation and an increase in production. This directly helps to reduce costs and increase efficiency in the production process. Also, this process can lead to the improvement of the final quality of paper products and ultimately lead to influence in the competitive market.

Considering these cases, paper shredding is a vital and fundamental step in the paper production process, which not only helps the productivity and efficiency of the process, but also helps to reduce costs and improve the final products. These measures will make the paper industry and the environment experience more productivity and efficiency.

Pulping paper

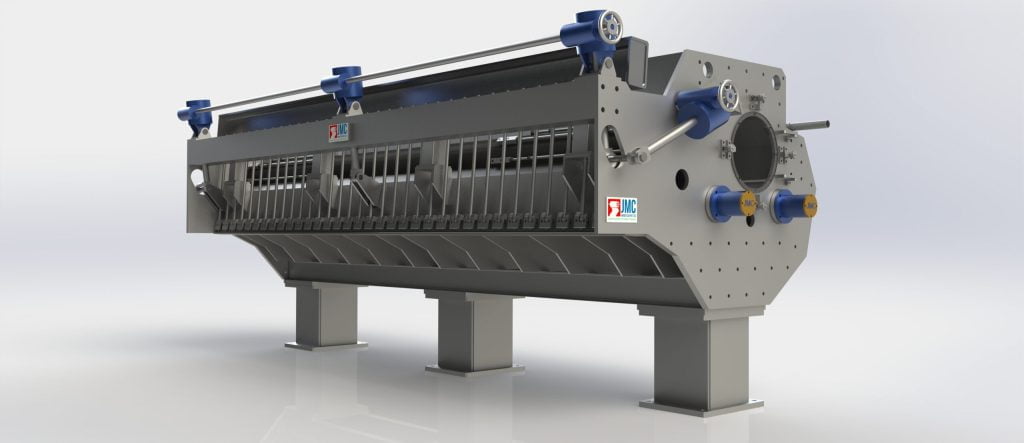

In the next stage of the paper production process, the shredded paper is mixed with water and chemicals by a machine called a pulper to turn it into pulp. This process is fundamental because by using a mixture of water and chemicals, the papers are recycled and produced into a pulp ready for the next steps.

Once pulped, these materials are passed through filters that only pass the pulp, while plastic waste and other impurities are separated. This stage of the recycling and paper production process is very important, because it is possible to purify the pulp and remove any impurity particles from it.

Filters used in papermaking lines have different types, each of which has specific tasks and applications. Among the filters used in this step, we can mention screening and separation filters, which play a very important role in improving the quality and purifying the dough.

Also, this stage of the paper production process requires the use of advanced and precise equipment, which is particularly important to use modern technologies. These technologies play an essential role in improving the final quality of paper products as well as process efficiency.

Compounding

In the paper recycling process, there is a step that applies to all paper recycling plants and to all types of paper. At this stage of the process, the pulp passes through large plates to remove impurities such as ink, staples, glue, etc. In addition, there is a more comprehensive filtration step where all non-fibrous foreign materials are removed. This is done in such a way that light materials such as plastic float to the top and heavy materials such as metals settle to the bottom. In general, in all paper recycling plants, there are two steps for pulp cleaning. The first stage, which is the combination of water and paper, and the second stage is dedicated to the use of chemicals to remove the ink.

Production of the final product

In the paper production process, at the final stage, the pulp is transferred to the production line and after drying, it is prepared in the form of rolls. After production, these paper rolls are transferred to other factories to prepare various subcategories of these types of rolls depending on the market needs.

These rolls have different uses depending on their type and weight. In fact, most of these rolls are used for the production of boxes and trays of sweets, packaging of various products, printing, etc. These things make these rolls play a very vital role in various industries and provide quality and necessary standards for the final products.

Paying attention to the details of the paper production process and different uses of paper rolls is important to increase general knowledge and better understanding for the audience. With this action, people will be able to learn more deeply about the paper production process and its important role in various industries.