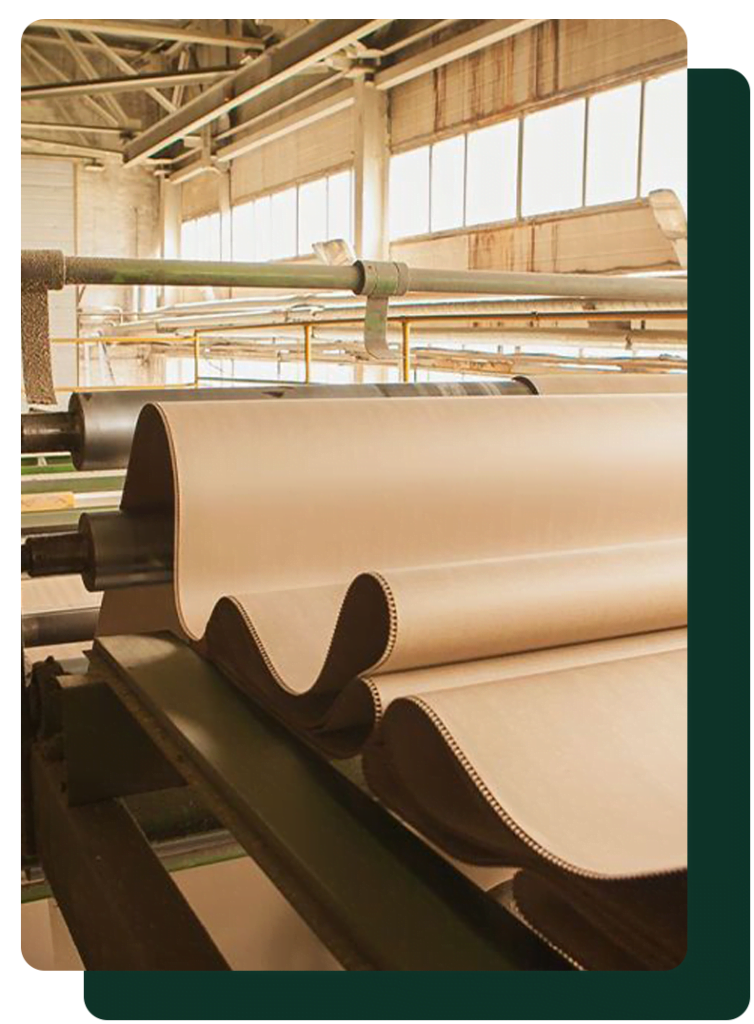

In the packaging industry, the main responsibility of supporting the weight and strength of the carton is the responsibility of the floating paper or Congress. There are different types of floating paper, which are classified according to the type of raw materials, production process and additives. Agricultural waste, wood pulp and recycled paper can be used to produce floating paper.

In order to use cardboard and cardboard waste as raw materials in the process of producing floating paper, industrial starch, sizing materials and chemicals are used. These materials are used to increase resistance to tension, pressure and bursting.

Floating paper is mainly used in the packaging industry, it is also used in the inner layers of cartons, and it has high efficiency. In addition to these uses, this type of paper is sometimes used to make prefabricated door screens, postal packages, and other items.

Pishtazan Cellulose Shargh company produces floating paper as one of the best types of packaging paper. This type of paper with different characteristics and qualities is used in different industries and can be produced and marketed with different standards. At Pishtazan Cellulose Shargh Company, we produce floating paper with the highest quality and use the best raw materials with very high resistance. You can contact us for purchase and more information.

The floating paper produced in Pishtazan Cellulose Shargh Company in weights of 120 to 160 grams per square meter has the following specifications and resistance parameters:

Fluting paper Technical Specification

| VALUE | UNIT | TEST METHOD | ITEM |

| 130±5 | g/m2 | ISO 536 | GSM |

| 200 | KN/m | ISO 12192 | RCT |

| 320 | KN/m | ISO 16945 | Cct |

| 280 | KN/m | ISO 7263-2 | Cmt |

| 110≤ | N | ISO 1924-2 | Tensile(MD) |

| 220≤ | Kpa | ISO 2758 | Burst |

| 0.21 | mm | ISO 534 | Thickness |

| 50≤ | g/m2 | ISO 535 | Cobb |

| 5-7 | % | ISO 2216 | Moisture |

Floating paper is a type of paper that consists of several layers and is used as the most important element in making boxes and packaging industries. This type of paper is suitable for use in production and packaging lines due to its characteristics such as resistance, lightness and high flexibility.

Paper weight (Basis Weight):

Usually, this paper is produced in different weights, including 175gsm, 150gsm, 120gsm and 200gsm.

Dimensions:

The width of the paper produced in Pishtazan Cellulose Shargh is different according to the needs of the customers.

Resistance:

This paper has high resistance to pressure and impact.

Print quality:

This type of paper has a high quality for printing and can be printed on it with high quality with high clarity and cleanliness.

Recyclability:

Most of the floating papers are made from recycled materials, which is very important in order to preserve the environment and reduce the consumption of natural resources.

Due to these features, floating paper is known as one of the right choices for packaging products and different shipments in different industries.

Floating paper is one of the types of paper that is made of high quality material during production, according to its applications. Due to the use of quality materials and advanced technologies, this type of paper has more resistance and strength than cheaper papers. This means that floating paper, with the right weight and thickness, provides resistance to tearing and crushing.

Compared to cheaper paper that is made of thinner layers, floating paper uses thicker layers that reduce the possibility of tearing and crushing. However, it is important to weigh your needs carefully before purchasing and make the right choice based on quality and price. In addition, buying directly from paper mills can help you save middlemen and additional costs. By buying directly, you can easily get the best floating paper at a reasonable price.